An important aspect is the implementation of the management software that the company wanted to support in order to allow a rapid and efficient organization of production and purchase planning, automatically managing the latter based on the customers’ delivery schedule.

- Development

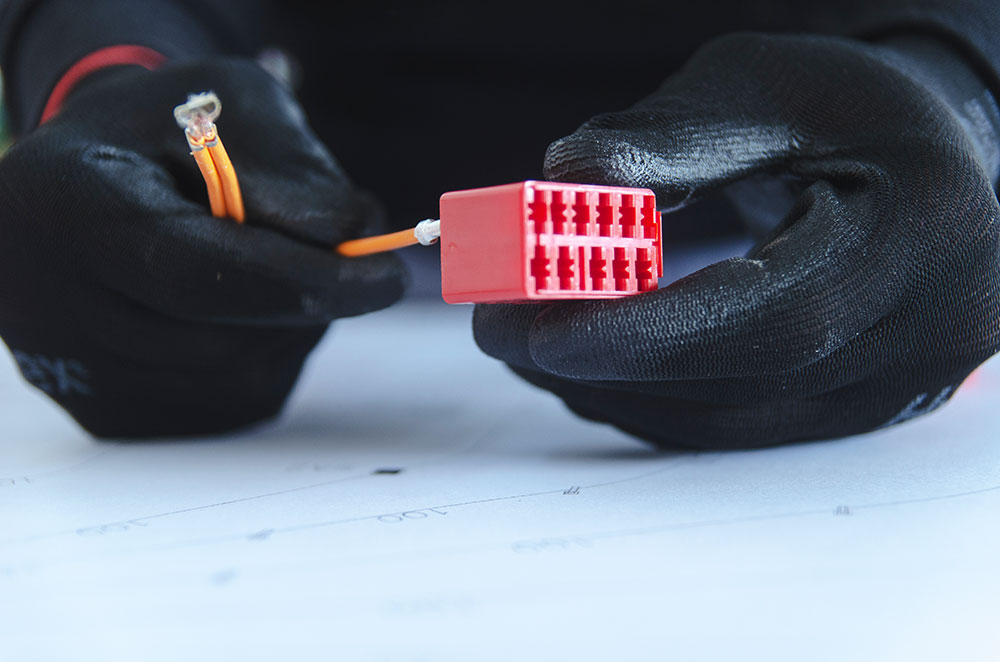

- cable cutting and crimping

- ultrasonic welds

- assembly and electrical testing on board

The ordinary production of Albac takes place through a very precise series of phases: according to the production plan, the cable cutting department realizes the cable pieces (cutting, stripping, crimping, marking), then the weldings are made with the Schunk machine before moving to the production department that produces the products then tested on electrical / dimensional test boards made by RGM.